K - SILICATE : A pure white, clear potassium base silicate mortar, Resist

highly concentrated Sulphuric acid and oxidizing acids. Used as a

bedding comment and not recommended where to waste water

collecting tanks. It resist Temperature upto 1900 C0 |

|

CNSL : Another bedding and jointing cement resist strong acids,

alkalies salts, etc. Most suitable as pipe jointing cement for

S.W. pipelines which leads effects water from different plants to

waste water collecting thanks. It resist Temperature up to 1900 C0 |

|

EPOXY : Most Windly applicable material against corrosion. Used as

coating, screeding, grouting and jointing material, Also used

for bonding old to new concrete. most suitable Where mild acids

are used. it resist Temperature upto 900 C0 |

|

SULPHUR : hot melt type acid-proof cement, resist oxidizing and non - oxidizing chemicals upto certain limits, Best jointing cement

for acid proof Brick lining. in Battery charging rooms. it

resist Temperature uptp 900 C0 |

|

POLYSTER : The basic material for FRP lining. Also used as a pointing

cement. resists certain acids, alkalies and natural salts. It

resist Temperature upto 900 C0 |

|

PRIMER : An industrial asphalt base anti-corrosive primer, Used to

protect structures against atmospheric corrosion and natural

salts. it resist Temperature upto 900 C0 |

|

MASTIC : A

hot melt type corrosion resistant cement in slab shape, Resists

dilute acids, alkalies, salts, etc... Best for heavy duty

industrial flooring and brick/tile inter-lining material.

Effective laying system for floors / elevated floors of

chemical storage tanks and yards. |

|

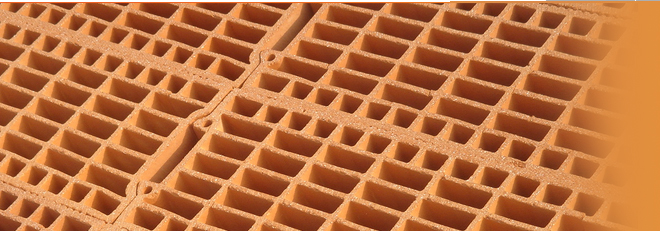

BRICKS and TILES

: Corrosion and heat resistant brick and tiles, Primary

material in corrosion technology available indifferent size and

thickness. |

|

CARBON - FILLED

CEMENTS : 100% cerbon filled cement for resistance against

Hydrofluoric acid, fluoride salts and other strong alkalies.

Carbon bricks and tiles of different sizes are also available |

|

REFRACTORY CEMENTS AND BRICKS : Is

grade high quality refractory cements are also available with us

like : Fire-create, Ramming mass, Fire clay, Super castables,

Accoset 50 Why heay A/K/C. insulation Mortars, etc... and

Refractory Bricks Is-6, Is-7, Is -8 Khapola Bricks, High Alumina

Bricks and Insulation Bricks. |

|

|

ACID

PROOF LINING |

|

1. BRICK LINING

: It is a prime lining system being use to stop corrosion

in major chemical projects. Bricks available in different sizes

are badded and jointed with acid proof cement. The cements being

used are depending on the chemical condition and

temperature upto its specific limitations. |

|

2. TILE LINING : It is generally use in Drainage systems, verticals, foundations,

Ceiling of the vessels, etc.... It is also badded & jointed with

different acid proof comments. tiles are available in different

size and thickness |

|

3. MANDANA STONE

LINING : It is generally use on chemical processing

floors, where it is badded & jointed with acid proof cements. |

|

4. EPOXY LINING

: It is solvent ferr, clear epoxy lining system used in

chemical storage tanks, pits, floors, ETP Tank... Lined in 3mm,

5mm and more thickness. it is highly recommended for Air crafts,

Breweries, Motor vehicle, Sugar, Dairy & Textile Projects. |

|

5. COLTAR EPOXY

LINING : It is Cottar bade Epoxy lining system being used

where mild acids, alkalies or waste water of low PH value takes

place. it has very good resistant for ETP, waste water

collecting chambers, Drains, etc. It is lined in 3mm, 5mm and

more thickness. |

|

6. CARBON BRICK

LINING : It is highly recommended where fluoride, Hydrofluoric

acids and very strong alkalies are use. Carbon

Bricks are available in different sizes, it is badded & jointed

with specially formulated carbon filled cements. |

|

7. F. R. P. LINING : It is Polyester

Resine base lining system useful where certain acids, alkalies

are used. Best for chemical & Reaction tanks, storage tank

foundations, Structures etc... it is available in 3mm, 5mm and

more thickness as per client requirements. |

| |

|

|

| TECHNICAL DATA |

| |

| |

Furane |

Phenolic |

K-

silicate |

CNSL |

sulphur |

Epoxy |

Polyester |

Bricks |

Mastic |

| color |

Black |

Black |

Off white |

Black |

Black |

Off white |

Off white |

Off white |

Black |

Ratio |

1.3 |

1.3 |

1.3 |

1.3 |

Hot Melt |

1:5 |

1:5 |

- |

Hot Melt |

Compressive

Strength

(Kg/Cm2) |

350 |

350 |

150 |

- |

250 |

500 |

500 |

700 |

250 |

Flexural

Strength

(Kg/Cm2) |

75 |

75 |

40 |

- |

70 |

150 |

150 |

200 |

70 |

Bond

Strength

(Kg/Cm2) |

10 |

10 |

5 |

- |

10 |

10 |

12 |

- |

10 |

Water

Absorption

(Max % ) |

1% |

1% |

18% |

1% |

1% |

1% |

1% |

2% |

1% |

Temperature

Resistant

Max C" |

1700 |

1700 |

9000 |

1900 |

900 |

900 |

900 |

9000 |

600 |

|

| |

| Rato = Solution : Power **

Absorption of Tulane -- Data not Available. |

| |

CHEMICAL RESISTANCE OF SILICATE TYPE MORTARS |

| |

| Sl

No. |

Substance |

Chemical Sodium

Silicate Type |

Resistance Potassium

Silicate Type |

| i) |

Hydrochloric acid (concentrated) |

R |

R |

| ii) |

Sulphuric acid (10%) |

R |

R |

| iii) |

Sulphuric acid (10 to 50 %) |

L |

R |

| iv) |

Sulphuric acid (above 50 %) (see

Note) |

N |

R |

| v) |

Nitric acid ( concentrated ) |

R |

R |

| vi) |

Organic acids ( concentrated ) |

R |

R |

| vii) |

Hydrochloric acid ( any strength

) |

N |

N |

|

| |

| Alkalies : |

| |

| i) |

Sodium Hydrochloric ( any strength ) |

N |

N |

| ii) |

Sodium

carbonate ( any strength ) |

N |

N |

|

| |

| Salt Solution : |

| |

| i) |

Acidic

(pH value than 4 ) |

R |

R |

| ii) |

Alkaline |

N |

N |

| iii) |

Neutral |

L |

L |

|

| |

| Solvents : |

| |

| i) |

Aliphatic hydrocarbons |

R |

R |

| ii) |

Aromatic

hydrocarbons |

R |

R |

iii)

|

Alcohols |

R |

R |

| iv) |

Ketones |

R |

R |

| v) |

Chlorinated

hydrocarbons |

R |

R |

|

| |

| Fats and oils. |

| |

Note - Potassium silicate mortar used for resistance of

Sulphuric acid (above 90% percent), for a prolonged period, may

cause crystal formation with subsequent growth within the pores

and can disintegrate these mortars. |

| |

CHEMICAL RESISTANCE OF RESIN TYPE MORTARS |

| |

| SL

NO. |

SUBSTANCE |

EPOXY |

POLYESTER |

PHENOLIC |

FURANE |

CASHEW

NUT

SHELL

LIQUID |

| |

Acids

: |

|

|

|

|

|

| i) |

Acetic acid 10% |

R |

R |

R |

R |

R |

| ii) |

Chromic acid

10% |

N |

R |

L |

N |

L |

| iii) |

Hydrochloric

acid (cone) |

R |

R |

R |

R |

R |

| iv) |

Hydrochloric

acid 40 % (see note 2) |

N |

N |

R |

R |

R |

| v) |

Lactic acid 2 % |

|

R |

R |

R |

R |

| vi) |

Nitric acid 10

% |

L |

N |

L |

N |

L |

| vii) |

Nitric acid

(cone) |

N |

N |

N |

N |

N |

| viii) |

Phosphoric acid

10 % |

R |

R |

R |

R |

R |

| ix) |

Sulphuric acid

10% |

R |

R |

R |

R |

R |

| x) |

Sulphuric acid

40% |

R |

R |

R |

R |

R |

| xi) |

Sulphuric acid

(cone) |

N |

N |

L |

N |

N |

|

| |

| Alkalies : |

| |

| i) |

Ammonia 0-880 |

R |

N |

L |

R |

R |

| ii) |

Sodium

hydroxide 40 % |

R |

N |

L |

R |

L |

| iii) |

Sodium

carbonate |

R |

L |

R |

R |

R |

| iv) |

Calcium

hydroxide |

R |

N |

R |

R |

R |

|

| |

| Salt Solution : |

| |

| i) |

Salt

solution (acidic) |

R |

R |

R |

R |

R |

| ii) |

Salt solution

(alkaline) |

R |

L |

R |

R |

R |

|

| |

| Solvents : |

| |

| i) |

Aliphatic hydrocarbons |

R |

R |

R |

R |

N |

| ii) |

Aromatic

hydrocarbons |

L |

N |

R |

R |

N |

| iii) |

Alcohols |

R |

R |

R |

R |

R |

| iv) |

Ketones |

L |

N |

L |

R |

R |

| v) |

Chlorinated

hydrocarbons |

L |

L |

R |

R |

N |

| |

Wet

Gases (oxidizing) |

N |

N |

N |

N |

N |

| |

Wet

Gases (reducing) |

R |

R |

R |

R |

R |

| |

Mineral

Oils |

R |

R |

R |

R |

L |

| |

Vegetable Oils and Fats |

R |

R |

R |

R |

L |

|

| |

| Note 1 - R = Generally Recommended, |

| L = Limited use

(occasional spillage), |

| N = Not Recommended. |

| |

| Note 2 - Carbon and graphite fillers should be used for hydrofluoric acid

service. |

| |

| TASTING FACILITIES

:- We have complete tasting facilities

chemicals as well as physical. |

| |

Top |